中空玻璃加工設(shè)備:解密 “空氣夾層” 的誕生工廠

時間:2025-07-04 來源:http://www.365cool.cn/ 發(fā)布人:昌盛機(jī)械

在建筑節(jié)能與工業(yè)玻璃制造領(lǐng)域,中空玻璃憑借兩層玻璃間的空氣夾層(通常 6-20mm),成為隔絕噪音、減少熱量傳遞的 “全能選手”。而這層看似簡單的 “空氣屏障”,實(shí)則需要一整條精密設(shè)備鏈的協(xié)同運(yùn)作。從玻璃原片的 “精準(zhǔn)剪裁” 到密封膠的 “無縫擁抱”,中空玻璃加工設(shè)備如同一位隱形的 “空間編織者”,用機(jī)械臂的舞動與傳感器的 “眼睛”,將普通玻璃轉(zhuǎn)化為兼具功能性與美觀性的復(fù)合產(chǎn)品。

In the fields of building energy efficiency and industrial glass manufacturing, insulated glass has become an all-around player in isolating noise and reducing heat transfer with the air interlayer between two layers of glass (usually 6-20mm). And this seemingly simple 'air barrier' actually requires the coordinated operation of a whole chain of precision equipment. From precise cutting of glass raw sheets to seamless embrace of sealants, insulated glass processing equipment is like an invisible "space weaver", using the movement of robotic arms and the "eyes" of sensors to transform ordinary glass into composite products that combine functionality and aesthetics.

原片玻璃的 “量體裁衣” 系統(tǒng)

The 'tailor-made' system for original glass sheets

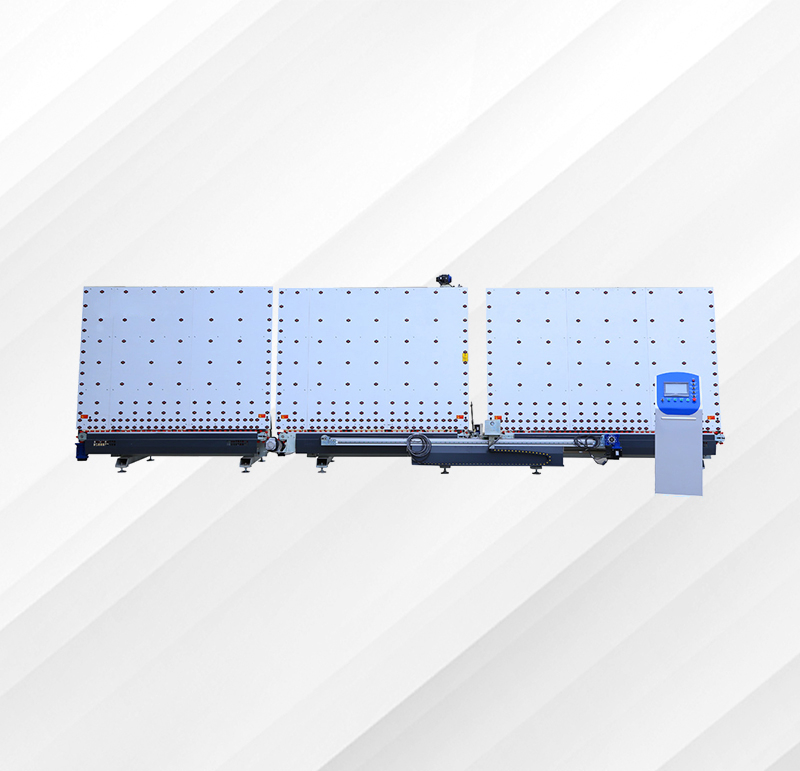

加工的起點(diǎn)是對玻璃原片的尺寸處理,這需要切割機(jī)與磨邊機(jī)的默契配合。切割機(jī)的核心是可高速旋轉(zhuǎn)的金剛石刀頭(硬度達(dá)莫氏 10 級),通過伺服電機(jī)控制其在玻璃表面劃出深度 0.3-0.5mm 的軌跡,配合真空吸附式工作臺(吸力達(dá) 80kPa)固定原片,確保切割尺寸誤差≤0.1mm。切割后的玻璃邊緣鋒利如刃,磨邊機(jī)的砂輪組(通常由粗砂輪、精砂輪、拋光輪三級組成)開始工作:粗砂輪(粒度 80-120 目)快速打磨出 45° 倒角,精砂輪(粒度 200-300 目)將邊緣粗糙度降至 Ra≤1.6μm,最后拋光輪(羊毛氈 + 拋光膏)賦予邊緣鏡面效果,避免應(yīng)力集中導(dǎo)致的玻璃自爆。整個過程中,紅外對中傳感器(精度 ±0.2mm)實(shí)時監(jiān)測玻璃位置,確保邊緣處理均勻一致。

The starting point of processing is the size treatment of the glass raw sheet, which requires the tacit cooperation between the cutting machine and the edging machine. The core of the cutting machine is a high-speed rotating diamond blade (with a hardness of 10 on the Mohs scale), which is controlled by a servo motor to draw a trajectory with a depth of 0.3-0.5mm on the glass surface. It is fixed with a vacuum adsorption worktable (with a suction force of 80kPa) to ensure that the cutting size error is ≤ 0.1mm. The edge of the cut glass is as sharp as a blade. The grinding wheel group of the edge grinder (usually composed of three stages: coarse grinding wheel, fine grinding wheel, and polishing wheel) starts working: the coarse grinding wheel (with a particle size of 80-120 mesh) quickly grinds out a 45 ° chamfer, the fine grinding wheel (with a particle size of 200-300 mesh) reduces the edge roughness to Ra ≤ 1.6 μ m, and finally the polishing wheel (wool felt+polishing paste) gives the edge a mirror effect to avoid stress concentration. Causing the glass to self destruct. Throughout the process, the infrared centering sensor (with an accuracy of ± 0.2mm) monitors the position of the glass in real-time to ensure uniform and consistent edge treatment.

潔凈度的 “嚴(yán)苛守護(hù)者”

The 'strict guardian' of cleanliness

玻璃表面的塵埃、油漬會直接影響后續(xù)密封效果,清洗干燥設(shè)備承擔(dān)著 “潔凈把關(guān)” 的重任。清洗段采用多組對輥式毛刷(刷毛材質(zhì)為尼龍 66,硬度邵氏 85A),以 1500rpm 的轉(zhuǎn)速配合去離子水(電導(dǎo)率≤10μS/cm)沖刷玻璃表面,毛刷壓力控制在 0.5-1.0N/cm?,既去除頑固污漬又不劃傷玻璃。清洗后的玻璃進(jìn)入烘干段,熱風(fēng)噴嘴以 80℃、20m/s 的氣流吹掃表面(風(fēng)速誤差≤5%),配合底部紅外加熱板(溫度均勻性 ±2℃),確保玻璃離開時表面含水率<0.1%。部分設(shè)備還配備靜電消除器,通過電暈放電中和玻璃表面電荷(殘留電壓≤100V),避免吸附空氣中的微塵。

Dust and oil stains on the surface of glass will directly affect the subsequent sealing effect, and cleaning and drying equipment bears the responsibility of "cleanliness control". The cleaning section uses multiple sets of roller type brushes (bristles made of nylon 66 with a hardness of 85A on the Shore scale) to wash the glass surface at a speed of 1500rpm with deionized water (conductivity ≤ 10 μ S/cm). The brush pressure is controlled between 0.5-1.0N/cm? Remove stubborn stains without scratching the glass. The cleaned glass enters the drying section, and the hot air nozzle blows the surface with an airflow of 80 ℃ and 20m/s (wind speed error ≤ 5%), combined with the bottom infrared heating plate (temperature uniformity ± 2 ℃), to ensure that the surface moisture content of the glass is less than 0.1% when it leaves. Some devices are also equipped with static eliminators, which neutralize the surface charges of the glass through corona discharge (residual voltage ≤ 100V), avoiding the adsorption of fine dust in the air.

間隔條的 “魔法塑形” 裝置

The 'magic shaping' device of the spacer bar

中空玻璃的核心支撐是鋁制間隔條,其加工需要折彎機(jī)與分子篩填充機(jī)的協(xié)同。折彎機(jī)的模具組(材質(zhì)為 Cr12MoV,硬度 HRC58-62)可根據(jù)需求彎出矩形、圓形等不同形狀,伺服電機(jī)驅(qū)動模具以 0.1mm 的精度控制折彎角度(誤差≤0.5°),確保間隔條閉合時接口間隙<0.2mm。填充分子篩的過程如同給間隔條 “注入干燥劑”,真空填充機(jī)通過負(fù)壓(壓力≤10kPa)將直徑 1-2mm 的球形分子篩(吸附量≥20% RH)吸入間隔條腔體,填充密度控制在 0.6-0.8g/cm?,既保證吸濕能力又避免過量導(dǎo)致間隔條變形。填充后,端部密封膠(丁基膠,黏度 1000-1500Pa?s)通過螺桿泵以 0.5mm 的厚度均勻涂布,將分子篩牢牢封存。

The core support of insulating glass is aluminum spacer bars, which require the cooperation of bending machines and molecular sieve filling machines for processing. The mold set of the bending machine (made of Cr12MoV material, hardness HRC58-62) can bend into different shapes such as rectangles and circles according to needs. The servo motor drives the mold to control the bending angle with an accuracy of 0.1mm (error ≤ 0.5 °), ensuring that the interface gap is less than 0.2mm when the spacer is closed. The process of filling the molecular sieve is like "injecting desiccant" into the spacer. The vacuum filling machine uses negative pressure (pressure ≤ 10kPa) to suck spherical molecular sieves with a diameter of 1-2mm (adsorption capacity ≥ 20% RH) into the spacer cavity, and the filling density is controlled at 0.6-0.8g/cm? Ensure moisture absorption capacity while avoiding excessive deformation of the spacer strip. After filling, the end sealant (butyl rubber, viscosity 1000-1500Pa? S) is evenly applied with a thickness of 0.5mm through a screw pump to firmly seal the molecular sieve.

合片與密封的 “精密對接” 環(huán)節(jié)

Precision docking link between lamination and sealing

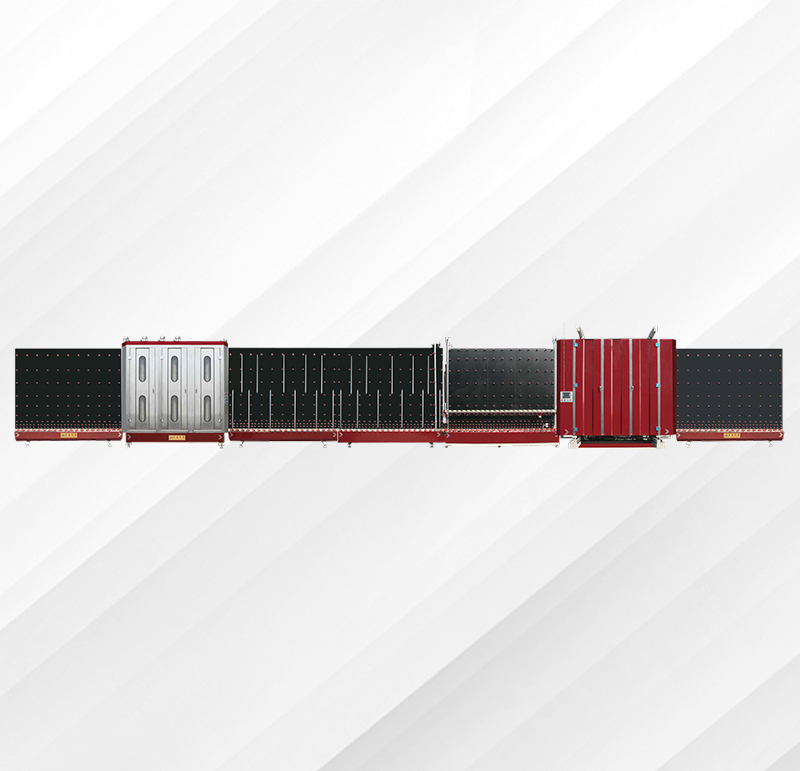

兩片處理好的玻璃需在合片設(shè)備上完成 “空氣夾層” 的構(gòu)建。真空吸附式合片機(jī)的上料臂(定位精度 ±0.3mm)將玻璃平穩(wěn)放置在工作臺,激光測距儀(精度 ±0.1mm)實(shí)時監(jiān)測間隔條位置,確保兩片玻璃的間距誤差<0.5mm。對于 Low-E 玻璃等鍍膜產(chǎn)品,設(shè)備自動識別膜面(通過光譜傳感器檢測反射率變化),避免鍍膜面朝向錯誤影響節(jié)能效果。合片后的玻璃進(jìn)入密封環(huán)節(jié),雙組份打膠機(jī)將丁基膠與硅酮膠分兩次涂布:內(nèi)層丁基膠(涂布速度 5-10m/min)形成第一道密封,隔絕空氣滲透;外層硅酮膠(固化時間 24-48h)提供結(jié)構(gòu)強(qiáng)度,膠層厚度控制在 8-12mm,通過壓力傳感器(精度 ±0.05MPa)確保膠量均勻,避免氣泡或斷膠。

Two pieces of processed glass need to be constructed with an "air interlayer" on the laminating equipment. The feeding arm of the vacuum adsorption laminating machine (positioning accuracy ± 0.3mm) smoothly places the glass on the workbench, and the laser rangefinder (accuracy ± 0.1mm) monitors the position of the spacer in real time to ensure that the distance error between the two pieces of glass is less than 0.5mm. For coated products such as Low-E glass, the equipment automatically identifies the film surface (detects changes in reflectivity through a spectral sensor), avoiding the influence of incorrect coating surface orientation on energy-saving effect. After the laminated glass enters the sealing process, the two-component glue machine applies butyl rubber and silicone rubber in two separate coats: the inner layer of butyl rubber (coating speed 5-10m/min) forms the first seal, isolating air infiltration; The outer layer of silicone adhesive (curing time 24-48 hours) provides structural strength, and the thickness of the adhesive layer is controlled at 8-12mm. The pressure sensor (accuracy ± 0.05MPa) ensures uniform adhesive volume and avoids bubbles or breakage.

本文由中空玻璃加工設(shè)備友情奉獻(xiàn).更多有關(guān)的知識請點(diǎn)擊:http://www.365cool.cn我們將會對您提出的疑問進(jìn)行詳細(xì)的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.365cool.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 中空玻璃加工設(shè)備:解密 “空氣夾層” 的誕生工廠 2025/07/04

- 雙組份打膠機(jī)的 “呼吸密碼”:解析耗氣量背后的門道 2025/07/03

- 封膠界的 “神級操盤手”:全閉環(huán)如何吊打開環(huán)與半閉環(huán) 2025/07/02

- 全自動封膠線:拆解 “智能涂膠” 的核心拼圖 2025/07/01

- 中空玻璃生產(chǎn)線:從原料到成品的 “規(guī)范通關(guān)秘籍” 2025/06/24

- 解鎖異形鋁條折彎密碼:全自動折彎機(jī)操作全流程解析 2025/06/20

- 中空玻璃生產(chǎn)線:一塊玻璃的 “變形計(jì)” 全記錄 2025/06/18

- 中空玻璃誕生記:加工設(shè)備使用全流程大揭秘 2025/06/17

- 全自動封膠線怕腐蝕嗎?揭秘其耐久性真相與防護(hù)秘訣 2025/06/16

- 中空玻璃加工設(shè)備組成結(jié)構(gòu)解析 2025/06/14

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: