中空玻璃生產(chǎn)線:從原料到成品的 “規(guī)范通關(guān)秘籍”

時間:2025-06-24 來源:http://www.365cool.cn/ 發(fā)布人:昌盛機械

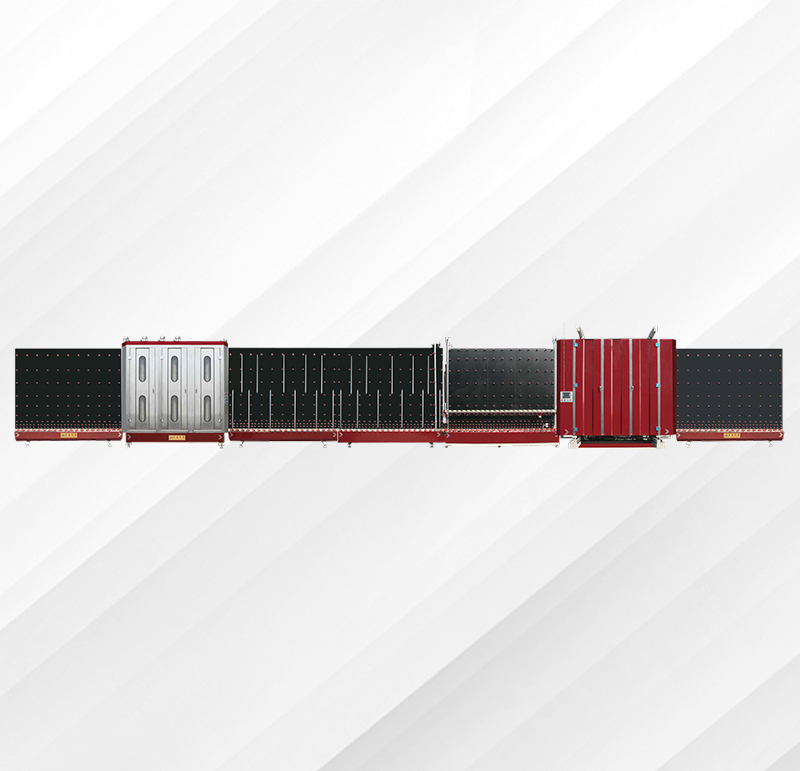

在建筑節(jié)能與采光需求日益增長的當下,中空玻璃憑借優(yōu)異的隔熱隔音性能成為市場 “寵兒”。而中空玻璃生產(chǎn)線如同精密的 “玻璃智造工廠”,從原片切割到密封合片,每一步操作都關(guān)乎產(chǎn)品質(zhì)量。想要駕馭這條生產(chǎn)線,必須嚴格遵循操作規(guī)范,才能確保產(chǎn)出高品質(zhì)的中空玻璃。

In the current era of increasing demand for building energy efficiency and lighting, insulated glass has become the "darling" of the market due to its excellent thermal and sound insulation performance. The production line of insulating glass is like a precision "glass intelligent manufacturing factory", from cutting raw sheets to sealing and laminating, every step of the operation is related to product quality. To operate this production line, it is necessary to strictly follow the operating procedures to ensure the production of high-quality insulated glass.

開機前:筑牢安全與準備的 “雙重防線”

Before startup: Build a "dual defense line" of safety and preparation

啟動生產(chǎn)線前,安全檢查與設(shè)備調(diào)試缺一不可。首先,操作人員需穿戴好防護裝備,包括安全帽、防護手套與護目鏡,避免玻璃碎屑劃傷或機械部件意外碰撞。其次,對生產(chǎn)線各環(huán)節(jié)進行全面 “體檢”:檢查傳輸輥道是否運轉(zhuǎn)順暢,確保無卡頓、異響;確認清洗干燥機的毛刷、風機與加熱裝置功能正常,避免因清洗不凈或干燥不充分影響后續(xù)工序;檢查密封膠涂布機的膠管是否堵塞、計量泵壓力是否穩(wěn)定,防止膠量不均導致密封失效。同時,還需檢查電控系統(tǒng)的線路連接與儀表參數(shù),確保設(shè)備運行參數(shù)處于安全范圍。此外,備好足量的干燥劑、密封膠、間隔條等耗材,并確認其質(zhì)量符合生產(chǎn)標準,為生產(chǎn)做好充足準備。

Before starting the production line, safety checks and equipment debugging are indispensable. Firstly, operators need to wear protective equipment, including helmets, gloves, and goggles, to avoid scratches from glass shards or accidental collisions with mechanical components. Secondly, conduct a comprehensive "physical examination" of each link of the production line: check whether the conveyor roller is running smoothly, ensuring no jamming or abnormal noise; Confirm that the brushes, fans, and heating devices of the cleaning and drying machine are functioning properly to avoid affecting subsequent processes due to incomplete cleaning or drying; Check if the rubber hose of the sealant coating machine is blocked and if the pressure of the metering pump is stable to prevent uneven adhesive volume from causing seal failure. At the same time, it is necessary to check the wiring connections and instrument parameters of the electronic control system to ensure that the operating parameters of the equipment are within a safe range. In addition, prepare sufficient desiccants, sealants, spacer strips and other consumables, and confirm that their quality meets production standards to make adequate preparations for production.

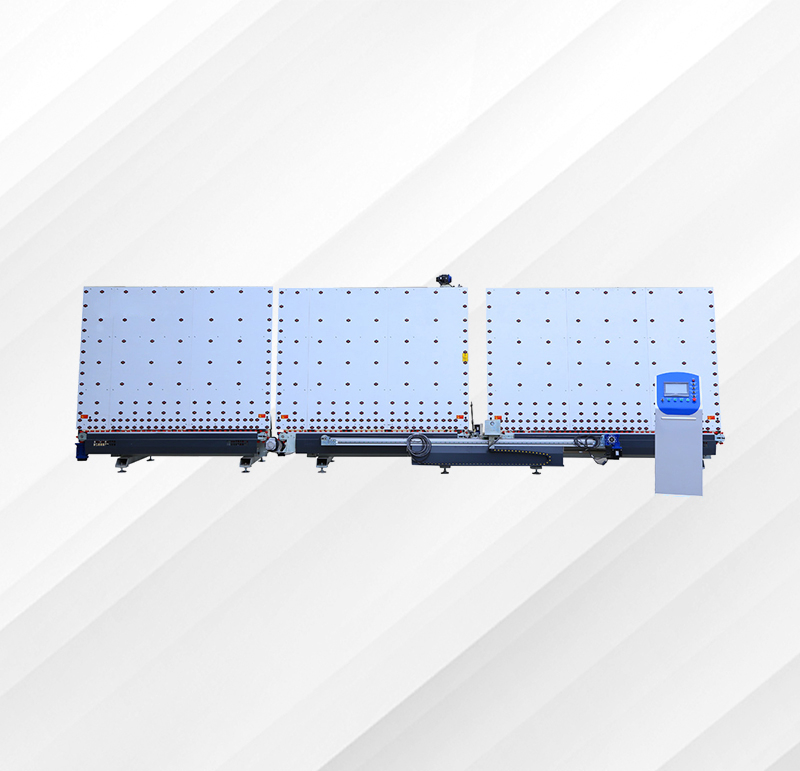

原片切割:尺寸精準的 “玻璃裁剪術(shù)”

Original cutting: precise size "glass cutting technique"

原片切割是生產(chǎn)的首道關(guān)鍵工序。根據(jù)訂單要求,操作人員需在控制系統(tǒng)中準確輸入玻璃的尺寸與數(shù)量,確保切割精度控制在 ±0.5 毫米以內(nèi)。切割時,應(yīng)勻速推進玻璃原片,避免因速度過快導致切割面不平整或崩邊;同時觀察切割刀輪的磨損情況,若發(fā)現(xiàn)刀痕變寬、玻璃邊緣出現(xiàn)鋸齒狀,需及時更換刀輪,保證切割質(zhì)量。切割后的玻璃需輕拿輕放,避免碰撞產(chǎn)生暗傷,并按尺寸分類存放,便于后續(xù)工序取用。此外,定期清理切割機臺面與廢料收集裝置,防止碎屑堆積影響設(shè)備運行。

Original cutting is the first critical process in production. According to the order requirements, the operator needs to accurately input the size and quantity of the glass in the control system to ensure that the cutting accuracy is controlled within ± 0.5 millimeters. When cutting, the glass sheet should be pushed at a constant speed to avoid uneven cutting surfaces or broken edges due to excessive speed; At the same time, observe the wear of the cutting wheel. If the knife marks become wider or the glass edges show jagged edges, the cutting wheel should be replaced in a timely manner to ensure cutting quality. The cut glass should be handled gently to avoid collision and hidden damage, and stored according to size for easy access in subsequent processes. In addition, regularly clean the cutting machine table and waste collection device to prevent debris accumulation from affecting equipment operation.

清洗干燥:打造潔凈表面的 “關(guān)鍵戰(zhàn)役”

Cleaning and drying: the 'key battle' for creating clean surfaces

清洗干燥環(huán)節(jié)直接影響中空玻璃的密封效果與使用壽命。將切割好的玻璃片平穩(wěn)放置在傳輸輥道上,確保玻璃與輥道貼合緊密,避免傳輸過程中偏移或滑落。清洗機通過毛刷與高壓水流去除玻璃表面的灰塵、油污,操作人員需監(jiān)控清洗液的濃度與污濁程度,當清洗液變渾濁或 pH 值超出正常范圍時,及時更換新液。清洗后的玻璃進入干燥區(qū),利用熱風或紅外加熱裝置快速蒸發(fā)水分,此時需關(guān)注干燥溫度與時間:溫度過低或時間過短會導致水分殘留,影響密封膠的粘結(jié)力;溫度過高則可能使玻璃表面產(chǎn)生熱應(yīng)力。干燥后的玻璃應(yīng)立即轉(zhuǎn)入下一工序,避免長時間暴露在空氣中二次吸附灰塵。

The cleaning and drying process directly affects the sealing effect and service life of insulated glass. Place the cut glass pieces steadily on the conveyor roller to ensure a tight fit between the glass and the roller, avoiding displacement or slipping during transportation. The cleaning machine uses a brush and high-pressure water flow to remove dust and oil stains from the glass surface. The operator needs to monitor the concentration and degree of contamination of the cleaning solution. When the cleaning solution becomes turbid or the pH value exceeds the normal range, it should be replaced with a new solution in a timely manner. After cleaning, the glass enters the drying area and quickly evaporates moisture using hot air or infrared heating devices. At this time, attention should be paid to the drying temperature and time: too low a temperature or too short a time can cause residual moisture, affecting the bonding strength of the sealant; If the temperature is too high, it may cause thermal stress on the surface of the glass. The dried glass should be immediately transferred to the next process to avoid prolonged exposure to air for secondary dust adsorption.

間隔框制作與填充:構(gòu)筑保溫隔音的 “隱形骨架”

Interval frame production and filling: constructing an "invisible skeleton" for insulation and sound insulation

間隔框的制作與填充決定了中空玻璃的隔熱性能。根據(jù)玻璃規(guī)格,使用彎角機或切割機將鋁間隔條加工成相應(yīng)尺寸的矩形框,拼接處需保證嚴絲合縫,防止漏氣影響中空層的密封效果。間隔框制作完成后,需填充足量的干燥劑,干燥劑應(yīng)具有良好的吸附性能,能有效吸收中空層內(nèi)的水分,避免玻璃內(nèi)部起霧。填充時需控制干燥劑的填充量,過少無法達到吸濕效果,過多則可能導致間隔框變形。填充完畢后,及時封閉間隔框兩端的開口,防止干燥劑散落或受潮失效。

The production and filling of spacer frames determine the thermal insulation performance of insulating glass. According to the glass specifications, use a corner bending machine or cutting machine to process the aluminum spacer into rectangular frames of corresponding sizes, and ensure that the joints are tightly sealed to prevent air leakage from affecting the sealing effect of the hollow layer. After the completion of the spacer frame production, a sufficient amount of desiccant should be filled. The desiccant should have good adsorption performance and be able to effectively absorb the moisture inside the hollow layer, avoiding fogging inside the glass. When filling, it is necessary to control the amount of desiccant filling. Too little cannot achieve the moisture absorption effect, and too much may cause deformation of the spacer frame. After filling, promptly seal the openings at both ends of the spacer to prevent the desiccant from scattering or becoming ineffective due to moisture.

合片與密封:鎖住性能的 “終極封印”

Splicing and Sealing: The Ultimate Seal for Locking Performance

合片是將兩片玻璃與間隔框組合成中空結(jié)構(gòu)的關(guān)鍵步驟。操作人員需雙手平穩(wěn)托起玻璃,將間隔框居中放置在下層玻璃表面,確保四個邊角對齊,再將上層玻璃精準覆蓋。合片過程中避免手指直接接觸玻璃內(nèi)表面,防止留下指紋或污漬影響美觀與性能。合片完成后,立即進行密封處理,先在間隔框兩側(cè)均勻涂布第一道丁基膠,形成初始密封層;隨后通過雙組份打膠機在玻璃四周涂布硅酮密封膠或聚硫密封膠,涂布時需控制膠層厚度與寬度,保證密封膠與玻璃、間隔框充分粘結(jié)。打膠完成后的中空玻璃需靜置固化,固化期間避免移動或震動,確保密封膠完全干燥,形成牢固的密封結(jié)構(gòu)。

Splicing is a key step in combining two pieces of glass with a spacer frame to form a hollow structure. The operator needs to steadily lift the glass with both hands, place the spacer frame in the center on the surface of the lower glass, ensure that the four corners are aligned, and then accurately cover the upper glass. During the lamination process, avoid direct contact between fingers and the inner surface of the glass to prevent fingerprints or stains from affecting its appearance and performance. After the lamination is completed, immediately perform sealing treatment by evenly applying the first layer of butyl rubber on both sides of the spacer frame to form the initial sealing layer; Subsequently, a two-component glue machine is used to apply silicone sealant or polysulfide sealant around the glass. During the application process, the thickness and width of the adhesive layer should be controlled to ensure that the sealant is fully bonded to the glass and spacer frame. After the completion of gluing, the insulated glass needs to be left to cure. During the curing period, avoid moving or shaking to ensure that the sealant is completely dry and forms a firm sealing structure.

收尾與維護:保障生產(chǎn)線的 “持久戰(zhàn)力”

Closing and Maintenance: Ensuring the 'Enduring Strength' of the Production Line

每日生產(chǎn)結(jié)束后,操作人員需對生產(chǎn)線進行全面清理與維護。清除設(shè)備表面與傳輸輥道上的玻璃碎屑、膠漬等雜物,避免其進入機械部件影響運行;對切割刀輪、毛刷輥、膠嘴等易損件進行檢查與保養(yǎng),及時更換磨損嚴重的部件;同時,檢查各潤滑點的潤滑油量,不足時及時補充。此外,還需對電控系統(tǒng)進行常規(guī)檢查,確保線路無松動、儀表顯示正常。定期對生產(chǎn)線進行精度校準與性能測試,如檢查切割尺寸誤差、密封膠涂布均勻性等,發(fā)現(xiàn)問題及時調(diào)整,保障生產(chǎn)線持續(xù)穩(wěn)定運行。

After daily production, operators need to conduct a comprehensive cleaning and maintenance of the production line. Remove glass debris, adhesive stains, and other debris from the surface of the equipment and the conveyor roller to prevent them from entering mechanical components and affecting operation; Inspect and maintain vulnerable parts such as cutting blade wheels, brush rollers, and rubber nozzles, and replace severely worn parts in a timely manner; At the same time, check the amount of lubricating oil at each lubrication point and replenish it promptly if it is insufficient. In addition, routine inspections of the electronic control system are required to ensure that the wiring is not loose and the instrument display is normal. Regularly perform precision calibration and performance testing on the production line, such as checking cutting size errors, sealant coating uniformity, etc. Any problems found should be adjusted in a timely manner to ensure the continuous and stable operation of the production line.

本文由中空玻璃生產(chǎn)線友情奉獻.更多有關(guān)的知識請點擊:http://www.365cool.cn我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.365cool.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 全自動封膠線:拆解 “智能涂膠” 的核心拼圖 2025/07/01

- 中空玻璃生產(chǎn)線:從原料到成品的 “規(guī)范通關(guān)秘籍” 2025/06/24

- 解鎖異形鋁條折彎密碼:全自動折彎機操作全流程解析 2025/06/20

- 中空玻璃生產(chǎn)線:一塊玻璃的 “變形計” 全記錄 2025/06/18

- 中空玻璃誕生記:加工設(shè)備使用全流程大揭秘 2025/06/17

- 全自動封膠線怕腐蝕嗎?揭秘其耐久性真相與防護秘訣 2025/06/16

- 中空玻璃加工設(shè)備組成結(jié)構(gòu)解析 2025/06/14

- 中空玻璃丁基膠涂布機制作流程解析 2025/06/13

- 中空玻璃加工設(shè)備怎么保障玻璃的密封性呢? 2025/06/12

- 全自動封膠線使用過程中有哪些要注意的地方? 2025/06/11

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當前位置:

當前位置: